Brand awareness is fundamental part of any marketing campaign whether it be through advertisement online, offline or through distributing gifts and goodies among consumers. The best way to spread awareness about your brand name or to engrave your brand logo in people’s mind is through custom gift items such as plastic keychain, stationary boxes, plastic pens, plastic fashion wrist bands or even a plastic gift box.

Even if you run a business by offering merchandise made up of plastics, you can cash in more customers by printing your business logo on the merchandise itself instead of just printing it on the paper enclosed inside the item box. This will not only give a unique look to your product but will also give a sense of confidence to your customers to differentiate between a genuine and fake product.

I recommend laser marking on plastics with a custom engraved logo on its front to leave a long lasting impression. Laser marking on plastics is long lasting, durable, cheap and can be molded to any unique shape you want.

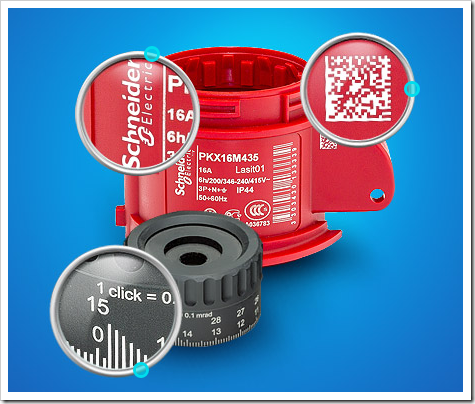

Laser marking is ideal for engraving any custom text, QR code, graphics or business logo (website logo) on any type of plastic material in an extremely flexible, fast and unique way.

If in case you are looking on how to laser mark your product then please note that plastic materials can easily be engraved with any quality laser engraving machine as long as the laser marking machine is resistant to wear and tear and does not require buying and specially disposing of expensive consumables such as inks, pastes or sprays.

There are a lot of laser marking machines online that you can buy to start marking your products yourself with an easy DIY user guide. The best in the market so far is the laser engraving machine is by LASIT.

Which Plastic Materials can be Laser Marked?

Plastic materials such as polycarbonate, ABS, polyamide, polyester, nylon etc. can be all laser marked permanently and easily. Depending on your marketing product or the material on your primary product of sale, every material reacts differently to laser marking process.

The major three marking processes worth mentioning are Foaming, Carbonization and Color Change.

Foaming Process

During foaming process, the laser light melts the surface of the plastic and then creates tiny gas bubbles on the material while cooling down. The gas bubbles , accumulated inside material expands the volume of the material, creating a sort of foamed plastic.

The laser marked part or the exposed part appears brighter compared to the non-exposed area and look slightly upraised from the surface.

Carbonization Process

During laser carbonization process the material is darkened on the exposed area. The chemical bonds in plastics are broken and carbon is released. This leads to discoloration of the exposed area which ranges from gray to bluish gray to black, giving a chromatic look and feel to the material.

Color Change Process

The color on plastic actually comes from absorbing the laser light. Upon heating the additives and carbon in plastics are destroyed and they vaporize.

During this process the color will change and foaming occurs. As a result of this localized heating and foaming, the dark plastics turn white on exposed area while clear plastics turn gray or black.

Now lets see how these laser markings actually look like on plastic products. Please see the following list of laser marked products as inspiration:

Laser Marking on a plastic card containing marked business logo, graphic, barcode, and QR code.

Laser marked brand logo and website address on a plastic product.

Laser marking on colorful plastic products.

Let me know if you already own a laser marking machine or if you have ever implemented laser marking on your business products for marketing purpose. Share your views and feedback with us by posting your comments below. Happy laser marking! 🙂

Speak Your Mind

You must be logged in to post a comment.